Taemane ea 55-degree e kentsoeng ka har'a carbide ea DCMT-21.51 e na le phomolo ea 7-degree. Sekoti se bohareng se na le countersink e le 'ngoe pakeng tsa likhato tse 40 le 60 le chip breaker e ka lehlakoreng le le leng feela. E na le botenya ba lisenthimithara tse 0.094 (3/32 inches), selikalikoe se ngotsoeng (I.C.) sa 0.25 ″ (1/4″), le sekhutlo (nko) radius e boholo ba 0.0156 inches (1/64 ″). DCMT21.51 (ANSI) kapa DCMT070204 ke lebitso le fanoeng ho kenyelletso (ISO). Sheba leqephe la "Compatibility" ho LittleMachineShop.com ho fumana lethathamo la lintho tse lumellanang le k'hamphani. Li-insert li ka rekoa ka bonngoe. Kahoo ha ho na tlhoko ea ho reka bongata ba lipalo tse leshome tse kentsoeng.

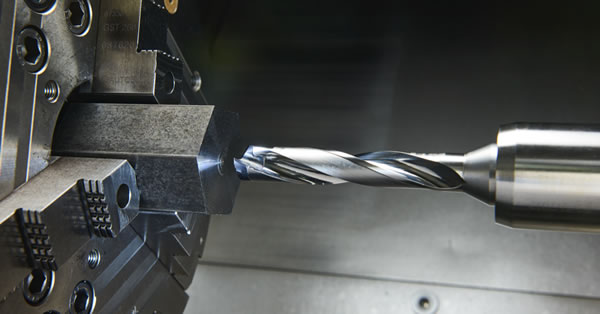

Lintho tse kentsoeng tsa DCMT ke lisebelisoa tse ka ntšoang tse ka hokeletsoang ho DCMTs. Hangata li-inserts tsena li boloka moeli oa sebele oa sesebelisoa. Likopo tsa ho kenya li kenyelletsa tse latelang:

borang

kaho

karohano le ho kgaola

ho phunya

grooving

hobbing

ho sila

meepo

saha

ho kuta le ho poma, ka ho latellana

ho tlanya

khoele

reteleha

brake rotor e potolohang

Likaroloana

Ho na le mefuta e mengata e fapaneng ea li-geometri bakeng sa ho kenya DCMT. Lintho tse kentsoeng tse chitja kapa tse chitja li sebelisoa lits'ebetsong tse kang ho sila likonopo le radius groove turning, ka ho latellana. Mefuta e meng e ka fetoloa e le hore libaka tse sa sebelisoeng tsa moeli li ka sebelisoa hang ha karolo ea moeli e se e felile.

kgutlotharo le kgutlotharo ka bobedi ke mehlala ya diforomo tse kenyang mahlakore a mararo. Tse kentsweng ka sebopeho sa dikgutlotharo di na le sebopeho sa kgutlotharo, ka mahlakore a mararo a lekanang ka bolelele le dintlha tse tharo tse nang le dikgutlo tse mashome a tsheletseng le leng le le leng. Ho kenya khutlotharo ke ntho e likhutlo li tharo e kentsoeng joaloka khutlo-tharo empa e na le sebōpeho sa khutlotharo e fetotsoeng. E ka nka sebopeho sa mahlakore a kobehileng kapa li-angles tse bohareng ka mahlakoreng, e leng se nolofalletsang hore li-angles tse khōloanyane li finyelloe lintlheng tsa ho kenya.

Lisebelisoa tsa DCMT

Litaemane, li-square, li-rectangles, le rhombic ke mehlala ea libopeho tse nang le mahlakore a mane a bitsoang li-insert. Ho tlosa lintho tse bonahalang, le ho kenya ka mahlakoreng a mane, 'me li-angles tse peli tse bohale li tsejoa e le ho kenya daemane. Malebela a ho seha sekwere a na le mahlakore a mane a lekanang. Ho kenya likhutlo li na le mahlakore a mane, 'me tse peli li le telele ho feta mahlakore a mang a mabeli. Grooving ke kopo e tloaelehileng bakeng sa lisebelisoa tsena; ntlha ea sebele ea ho itšeha e fumaneha metseng e khutšoanyane ea ho kenya. Li-insert tse tsejoang e le rhombic kapa parallelograms li na le mahlakoreng a mane 'me li na le mahlakoreng a mane ho fana ka tumello bakeng sa ntlha ea ho seha.

Li-insert li ka boela tsa etsoa ka sebōpeho sa pentagon, e nang le mahlakore a mahlano a lekanang ka bolelele, le li-octagonal tse kenyang, tse nang le mahlakore a robeli.

Mefuta e fapa-fapaneng ea ho kenya e ka khetholloa ho e mong ho latela li-angles tsa lintlheng tsa ho kenya, ho phaella ho geometry ea ho kenya ka boeona. Keketso e nang le "ball nose" ea hemispheric eo radius ea eona e leng halofo ea bophara ba sehahole e tsejoang e le leloala la nko la bolo. Mofuta ona oa leloala o sebetsa hantle bakeng sa ho seha li-semicircles tsa basali, li-grooves kapa radii. Ka tloaelo e sebelisoa ho li-milling cutters, leloala la "radius tip" ke leloala le otlolohileng le nang le radius ea ho sila lintlheng tsa mathōko. Ka tloaelo li khomaretsoe ho li-milling cutter holders, li-milling tip Mills li tlameha ho kenya mahlakoreng kapa lipheletsong tse nang le sebaka se nang le mahlakoreng ntlheng. Karolo ena e lumella leloala ho etsa sesebediswa sa mosebetsi se nang le sehiloeng se nang le angled kapa moeli oa chamfered. Keketso e tsejoang ka hore ke dogbone e na le likarolo tse peli tse sehiloeng, mokokotlo o mosesaane, 'me, joalo ka ha lebitso le bontša, likarolo tse pharaletseng tsa ho itšeha lipheletsong ka bobeli. Hangata, mofuta ona oa ho kenya o sebelisoa bakeng sa grooving. Karolo ea ntlha e kenyelletsoeng e ka tloha ho likhato tse 35 ho isa ho tse 55, hammoho le likhato tse 75, 80, 85, 90, 108, 120 le 135.

Litlhaloso

Ka kakaretso, kasert size e arotsoe ho ea ka selikalikoe se ngotsoeng (I.C.), se tsejoang hape e le bophara ba selikalikoe se lekanang ka har'a geometry e kentsoeng. Sena se sebelisoa bakeng sa lintho tse ngata tse kentsoeng ka har'a indexable, ntle le tse ling tsa khutlonnetsepa le tse ling tsa parallelogram, tse sebelisang bolelele le bophara. Litlhoko tsa bohlokoa tsa ho kenya DCMT ke botenya, radius (haeba ho hlokahala), le angle chamfer (ha ho hlokahala). Mantsoe “unground,” “indexable,” “chip breaker,” le “dished” a sebelisoa hangata ho hlalosa litšobotsi tsa DCMT tse kentsoeng. Li-attachments bakeng sa ho kenya li ka phunyeletsoa kapa tsa se be le lesoba.

Lisebelisoa

Carbide, micro-grain carbides, CBN, ceramic, cermet, cobalt, taemane PCD, tšepe ea lebelo le phahameng, le silicon nitride ke lisebelisoa tse atileng ka ho fetisisa tse sebelisoang kahong ea lisebelisoa tsa DCMT. Ho apara ho hanyetsa le ho kenya bophelo ho ka eketsoa ka bobeli ka tšebeliso ea liphahlo. Liaparo tsa ho kenya DCMT li kenyelletsa titanium nitride, titanium carbonitride, titanium aluminium nitride, aluminium titanium nitride, aluminium oxide, chromium nitride, zirconium nitride, le diamond DLC.