Idayimane le-55-degree ekufakweni kwe-carbide ye-DCMT-21.51 inokukhululeka okungama-degree angu-7. Imbobo emaphakathi inosinki owodwa ophakathi kuka-40 no-60 degrees kanye ne-chip breaker ehlangothini olulodwa kuphela. Ifaka ukujiya okungama-intshi angu-0.094 (3/32 amayintshi), indilinga ebhaliwe (I.C.) ka-0.25″ (1/4″), kanye nerediyasi yekhona (ikhala) ekala amayintshi angu-0.0156 (1/64″). I-DCMT21.51 (ANSI) noma i-DCMT070204 igama elinikezwe okokufaka (ISO). Bheka ikhasi elithi “Compatibility” ku-LittleMachineShop.com ukuze uthole uhlu lwezinto ezihambisana nenkampani. Okufakiwe kungase kuthengwe kanyekanye. Ngakho-ke asikho isidingo sokuthenga inqwaba yezibalo eziyishumi zokufaka.

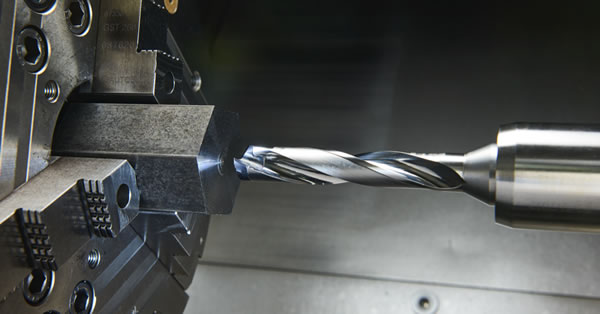

Okufakiwe kwe-DCMT kuyizinsiza ezikhiphekayo ezingase zinamathiselwe kuma-DCMT. Lezi zinto ezifakiwe zivame ukufaka umphetho wangempela wokusika wethuluzi. Izicelo zokufakwa zihlanganisa lokhu okulandelayo:

yisicefe

ukwakhiwa

ukwehlukana nokunqunywa

ukubhoboza

ukugebenga

ukuzilibazisa

ukugaya

izimayini

ukusaha

ukugunda nokusika, ngokulandelana

ukuthepha

ukuthunga

ukuphenduka

i-brake rotor iyajikeleza

Izici

Kunenhlobonhlobo ebanzi yamajiyometri okufakwayo kwe-DCMT. Okufakwayo okuyindilinga noma okuyindilinga kusetshenziswa ezinqubweni ezifana nokugaya inkinobho nokujika kwe-radius groove, ngokulandelanayo. Ezinye izinhlobo zingalungiswa ukuze izindawo ezingasetshenzisiwe zonqenqema zikwazi ukusetshenziswa uma ingxenye yonqenqema isigugile.

Unxantathu nonxantathu yizibonelo zamafomu okufaka anezinhlangothi ezintathu. Okufakwe ngendlela yonxantathu kunesimo esingunxantathu, nezinhlangothi ezintathu ezilingana ngobude namaphoyinti amathathu ahlanganisa ama-engeli angama-degree angamashumi ayisithupha lilinye. I-trigon insert iyisifaka esinamakhona amathathu esifana nonxantathu kodwa esinomumo ongunxantathu oshintshiwe. Kungathatha uhlobo lwezinhlangothi ezigobile noma ama-engeli amaphakathi ezinhlangothini, okuvumela ama-engeli ahlanganisiwe amakhulu ukuthi azuzwe ezindaweni zokufaka.

Ukufakwa kwe-DCMT

Amadayimane, izikwele, ama-rectangles, kanye ne-rhombic yizibonelo zamafomu anezinhlangothi ezine ezibizwa ngokuthi ama-insert. Ukukhipha impahla, nokufaka okunezinhlangothi ezine, nama-engeli amabili acijile aziwa ngokuthi ukufakwa kwedayimane. Amathiphu okusika isikwele afaka izinhlangothi ezine ezilinganayo. Okufakiwe okuwunxande kunezinhlangothi ezine, kanti ezimbili zinde kunezinye izinhlangothi ezimbili. I-Grooving iyisicelo esivamile salokhu kufakwa; umkhawulo wokusika wangempela utholakala emaphethelweni amafushane okufaka. Okufakiwe okwaziwa ngokuthi ama-rhombic noma amapharalelogramu anezinhlangothi ezine futhi ane-engeli kuzo zonke izinhlangothi ezine ukuze anikeze imvume yendawo yokusika.

Okufakiwe kungenziwa futhi ngesimo se-pentagon, enezinhlangothi ezinhlanu ezilingana ngobude, kanye nokufaka okuyi-octagonal, okunezinhlangothi eziyisishiyagalombili.

Izinhlobo ezihlukahlukene zokufaka zingahlukaniswa komunye nomunye ngokusekelwe kuma-angles we-tip of the inserts, ngaphezu kwe-geometry yezinto ezifakiwe ngokwazo. I-insert "enekhala lebhola" eline-hemispheric, i-radius yayo enguhhafu wobubanzi be-cutter eyaziwa ngokuthi i-ball nose mill. Lolu hlobo lwesigayo luhle kakhulu ekusikeni ama-semicircles wesifazane, ama-grooves, noma ama-radii. Ngokujwayelekile isetshenziswa kuma-gritter cutter, i-radius tip tip iyisigayo esiqondile esine-radius yokugaya emaphethelweni okusika. Ngokuvamile exhunywe kubambi be-milling cutter, izigayo zethiphu ye-chamfer kufanele zifake izinhlangothi noma iziphetho ezinendawo e-engeli phezulu. Lesi sigaba sivumela isigayo ukuthi senze isiqeshana sokusebenza esine-angled cut noma i-chamfered edge. Into efakwayo eyaziwa ngokuthi i-dogbone inemiphetho emibili yokusika, i-core core encane, futhi, njengoba igama liphakamisa, izici zokusika ezibanzi kuzo zombili iziphetho. Lolu hlobo lokufaka ngokuvamile lusetshenziselwa ukugoba. I-engeli yethiphu efakiwe ingaba kusuka ku-35 kuya ku-55 degrees, kanye nama-75, 80, 85, 90, 108, 120, kanye nama-degree angu-135.

Imininingwane

Ngokuvamile, kuusayizi wokusetha uhlukaniswa ngokwendingilizi ebhaliwe (I.C.), owaziwa nangokuthi ububanzi besiyingi obungena ngaphakathi kwejometri efakiwe. Lokhu kusetshenziselwa ukufaka okuningi okunenkomba, ngaphandle konxande nokunye okufakwayo kwepharalelogramu, okusebenzisa ubude nobubanzi esikhundleni salokho. Izidingo ezibalulekile zokufaka i-DCMT ubukhulu, irediyasi (uma ikhona), kanye ne-engeli ye-chamfer (uma ikhona). Amagama athi “unground,” “indexable,” “chip breaker,” kanye “dished” avame ukusetshenziswa ukuchaza izici zokufakwa kwe-DCMT. Okunamathiselwe kokufakwayo kungase kufakwe ngezikulufu noma kungabi nembobo.

Izinto zokwakha

I-Carbide, i-micro-grain carbides, i-CBN, i-ceramic, i-cermet, i-cobalt, i-PCD yedayimane, insimbi enesivinini esikhulu, ne-silicon nitride izinto ezivame kakhulu ezisetshenziswa ekwakhiweni kokufakwa kwe-DCMT. Ukumelana nokugqoka kanye nokuphila kokufaka kungandiswa kokubili ngokusetshenziswa kwezingubo. Izingubo zokufakwa kwe-DCMT zifaka i-titanium nitride, i-titanium carbonitride, i-titanium aluminium nitride, i-aluminium titanium nitride, i-aluminium oxide, i-chromium nitride, i-zirconium nitride, nedayimane DLC.