WNMG FAKA IZINHLOKO

I-CHIPBREAKER

Qeda ukusika (FH) inketho yokuqala ye-carbon steel, i-alloy steel, kanye nokuqedwa kwensimbi engagqwali. I-chip breaker enezinhlangothi ezimbili. Ngisho nasezindaweni ezijulile zokusikwa, ukulawulwa kwe-chip kuzinzile

Ukujula kokusika: kufika ku-1m

0.08 kuya ku-0.2mm isilinganiso sokuphakelayo

LM

I-LM imele ukusika okulula. Ukulawulwa kwe-Burr kuhle kakhulu. Ngenxa yokuthi izimfanelo zobukhali namandla onqenqema athuthukiswa ngama-engeli ahlukahlukene, ukwenzeka kwama-burrs kuyancipha kakhulu.

Ukujula kokusika: 0.7 - 2.0

Imvamisa yokudla: 0.10 - 0.40

LP

LP - Ukusika okulula kakhulu. Ama-butterfly protrusions enzelwe izimo ezithile zokusika. Ama-chips agoqeka phezulu, anciphisa ukumelana nokusika futhi abangele ukuqedwa okungcono kwendawo. I-breaker protrusion imelana ngendlela ehlukile ukugqokwa ngisho naphakathi kokugaya ngesivinini esikhulu, okuvumela ubude besikhathi sokuphuka okuqinile kwe-chip. Ama-Excels at copy machining: anomumo ocijile onqenqemeni okhiqiza ukuphuka okuhle kwe-chip ngesikhathi somshini wokukopisha futhi ohlehlisa ukuqondiswa kobuso bemishini.

Ukujula kokusika: 0.3 - 2.0

Izinga lokuphakelayo: 0.10 - 0.40

GM

I-GM - I-sub breaker ye-LM kanye ne-MM chipbreaker. Ukuze usike ukukhanya okuphakathi nendawo, inokumelana ne-notch okuhle kakhulu.

Ukujula kokusika: 1.0 - 3.5

Izinga lokuphakelayo: 0.10 - 0.35

MA

I-MA - I-medium carbon and alloy steel cutting. I-chip breaker inezinhlangothi ezimbili kanye nomhlaba omuhle wesenzo esiqinile sokusika.

Ukujula kokusika: 0.08 kuya ku-4mm

0.2 kuya ku-0.5 mm

MP

Izinga lokuphakelayo kwe-MP - Ukusika okuphakathi. Ifanele izimo ezihlukahlukene zokuguqula ikhophi, isuse isidingo sezinhlobo ezihlukene zokufaka. Uhlangothi lwangaphakathi lwe-butterfly protrusion luqukethe i-gradient ebukhali, ethuthukisa ukusebenza kahle kokuphulwa kwe-chip ekusikekeni okuncane.

Ukujula kokusika: 0.3 - 4.0

Izinga lokuphakelayo: 0.16 - 0.50

MS

I-MS - Izinga lokusika elimaphakathi lezinto okunzima ukuya kuzo emshinini. Ilungele ama-alloys asekelwe ku-nickel, i-titanium, nensimbi engagqwali.

Ukujula kokusika: 0.40-1.8

Izinga lokuphakelayo: 0.08 - 0.20

MW

I-MW - Ukufakwa kwe-Wiper kokusika kwe-carbon medium kanye ne-alloy steel. I-Chipbreaker inezinhlangothi ezimbili. I-wiper ingaphinda kabili izinga lokuphakelayo. Isikhwama esikhulu se-chip sinciphisa ukugxuma.

Ukujula kokusika: 0.9 - 4.0

Izinga lokuphakelayo lokusika okungalungile: 0.20 - 0.60

RM

I-RM Ukumelana nokuphuka okuvelele. Ukuzinza okuphezulu konqenqema kufezwa ngesikhathi somshini ophazamisekile ngokulungisa i-engeli yomhlaba kanye nokucija ijometri.

Ukujula kokusika: 2.5 - 6.0

Izinga lokuphakelayo lokusika okungalungile: 0.25 - 0.55

RP

I-RP I-peninsular protrusion yenzelwe ukusika okungalungile. Ubuso bokusika obutshekile bunciphisa ukuguga kwe-crater futhi buvimbele ukuvala. Ukumelana nokuqhekeka okuphezulu: umtshingo wokusika unefomu eliqinile lezwe eliyisicaba kanye nephakethe le-chip elikhulu ukuvimbela ukuvala nokuphuka ngesikhathi sokuncelisa.

Ukujula kokusika: 1.5 - 6.0

Imvamisa yokudla: 0.25 - 0.60

Faka nezinkinga.

Yiziphi izici okufanele isitolo sizicabangele lapho sikhetha into efakwa ohlwini yohlelo lokusika? Ezimweni eziningi, lena cishe akuyona indlela okufinyelelwa ngayo isinqumo.

Esikhundleni sokuzenzakalela kokujwayelekile, indlela engcono kakhulu ukuhlola inqubo yokusika ngokuningiliziwe bese ukhetha into efakwayo enezici ezifanele ukwanelisa izidingo nezimfuneko zalolo hlelo lokusebenza. Abahlinzeki bokufaka bangaba usizo olukhulu kulokhu. Ubuchwepheshe babo bungakuholela ekufakeni okulungele umsebenzi othile kodwa futhi okuzosiza ukukhulisa umkhiqizo nempilo yamathuluzi.

Ngaphambi kokuthatha isinqumo ngokufaka okungcono kakhulu, amabhizinisi kufanele ahlole ukuthi ithiphu lokusika elikhiphekayo liyisixazululo esingcono sephrojekthi kunethuluzi elithembekile. Esinye sezici ezikhanga kakhulu zokufakwayo ukuthi ngokuvamile kunomkhawulo wokusika ongaphezu kowodwa. Uma unqenqema lokusika luguga, lungashintshwa ngokuzungezisa noma ukuphenyisisa okufakiwe, okuvame ukwaziwa ngokuthi ukukhomba, kolunye uhlangothi.

Kodwa-ke, okufakiwe okunenkomba akufani no-hard njengamathuluzi aqinile ngakho-ke awanembi kangako.

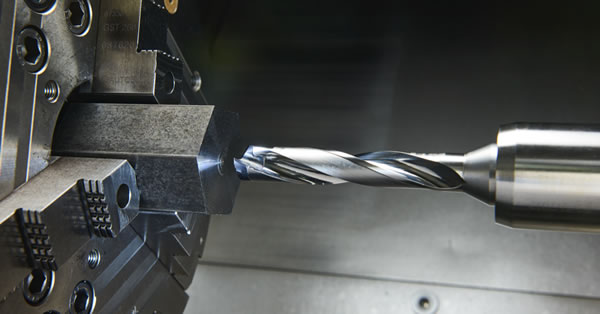

UKUQALA INKQUBO

Lapho ukhetho lokusebenzisa i-indexable insert lwenziwa, abathengisi babhekene nenqwaba yamathuba. Nquma ukuthi yini ofuna ukuyizuza ngokufaka njengendawo ekahle ongaqala ngayo ukuyikhetha. Nakuba ukukhiqiza kungase kube into esemqoka ezinhlanganweni ezithile, abanye bangase bazise ukuguquguquka okwengeziwe futhi bakhethe okufakiwe okungasetshenziswa ukukhiqiza izinhlobo eziningana zezingxenye ezifanayo, waphawula.

Esinye isici okufanele icatshangelwe ekuqaleni kwenqubo yokukhetha yokufaka isicelo, okungukuthi, okokusebenza okuzokwenziwa ngomshini.

Amathuluzi okusika esimanje aqondene nezinto ezithile, ngakho awukwazi nje ukukhetha ibanga elifakayo elisebenza kahle ngensimbi futhi ulindele ukuthi lizosebenza kahle ku-stainless, superalloy, noma i-aluminium.”

Abenzi bamathuluzi banikeza amamaki okufaka amaningana - ukusuka kokungagugi kakhulu kuye kwaqina - kanye namajiyometri ukuze abambe inhlobonhlobo yezinto zokusebenza, kanye nezimo zempahla ezinjengobulukhuni nokuthi ingabe into iyasakazwa noma ifojiwe.

Uma (usika) into ehlanzekile noma eyenziwe ngomshini, inketho yakho yebanga izohluka kunalapho (usika) uhlaka noma ingxenye yomgunyathi. Ngaphezu kwalokho, ukukhetha kwejiyomethri kwengxenye yabalingisi kuzohluka kulokho okwenziwa ngomshini ngaphambilini.”

Izitolo kufanele futhi zicabangele imishini lapho okuzofakwa khona