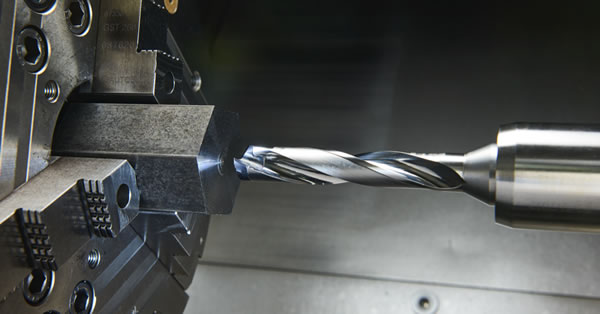

TYPES OF CARBIDE DRILL BITS

Carbide drill bits come in various types, each designed for specific drilling tasks and materials. Understanding the differences between these types will help you make an informed decision when selecting the right drill bit for your project.

Solid Carbide Drill Bits:Solid carbide drill bits are made entirely from carbide material, and their design allows for precise and efficient drilling. These bits are ideal for high-speed drilling and can handle a wide range of materials, including steel, aluminum, and composites. The absence of a separate shank enhances stability during drilling, reducing the risk of wandering or deviation from the desired hole.

Carbide Tipped Drill Bits:Carbide-tipped drill bits combine the toughness of high-speed steel with the hardness of carbide. The cutting edges are tipped with carbide inserts, which provide enhanced cutting performance and longevity compared to traditional high-speed steel drill bits. These bits are suitable for drilling hardened steel and abrasive materials.

Indexable Carbide Drill Bits:Indexable carbide drill bits feature replaceable carbide inserts on the cutting edge. This design allows for easy and cost-effective maintenance since you can replace the inserts when they become dull or damaged instead of replacing the entire drill bit. These drill bits are commonly used in large-scale drilling operations.

CARBIDE DRILL BIT APPLICATIONS

WHAT MATERIALS CAN I DRILL WITH CARBIDE DRILL BITS?

Carbide drill bits are versatile and robust tools that excel in drilling through a wide range of materials. The unique properties of carbide, a compound of carbon and other elements like tungsten, make these drill bits suitable for tackling tough and abrasive materials with ease.

One of the primary materials that carbide drill bits are well-suited for is metal. Whether it’s soft metals like aluminum or hard metals like stainless steel, carbide drill bits can maintain their sharpness and durability, providing efficient and precise drilling performance. This makes them popular choices in industries like automotive, aerospace, and manufacturing, where metal drilling is common.

Additionally, carbide drill bits are highly effective for drilling through masonry and concrete. The hardness and wear resistance of carbide make these bits capable of withstanding the abrasive nature of these materials, resulting in cleaner and more accurate holes. Construction workers, masons, and contractors often rely on carbide drill bits when working on projects that involve concrete and other masonry materials.

Furthermore, woodworkers also find carbide drill bits beneficial when drilling through hardwoods and dense materials. The sharp cutting edges of the carbide tips can handle the demanding drilling requirements of these materials, ensuring clean and splinter-free holes.

Beyond these common applications, carbide drill bits can also be used to drill through fiberglass, plastics, composites, and even some ceramics. Their versatility and ability to maintain sharpness in challenging conditions make them a valuable tool in various industries and DIY projects.

In summary, carbide drill bits are suitable for drilling through a wide range of materials, including metals, masonry, wood, plastics, and composites. Their exceptional hardness, wear resistance, and cutting capabilities make them a reliable choice for professionals and DIY enthusiasts alike, enabling them to tackle diverse drilling tasks efficiently and effectively.