The 55-degree diamond on the DCMT-21.51 carbide insert has a 7-degree relief. The central hole has a single countersink between 40 and 60 degrees and a chip breaker that is only on one side. It features a thickness of 0.094 inches (3/32 inches), an inscribed circle (I.C.) of 0.25″ (1/4″), and a corner (nose) radius measuring 0.0156 inches (1/64″). DCMT21.51 (ANSI) or DCMT070204 is the designation given to the insert (ISO). Check out the ” Compatibility ” page on LittleMachineShop.com to get a list of the company’s compatible items. Inserts may be purchased singly. Thus there is no requirement to purchase a ten-count bundle of inserts.

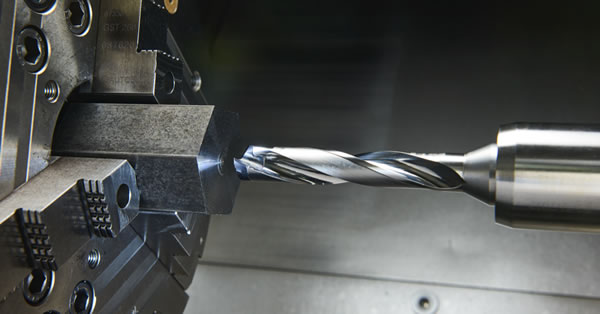

DCMT inserts are detachable accessories that may be attached to DCMTs. These inserts often house the actual cutting edge of the tool. Applications for inserts include the following:

boring

construction

separation and cutting off

drilling

grooving

hobbing

milling

mining

sawing

shearing and chopping, respectively

tapping

threading

turning

brake rotor rotating

Features

There is a wide variety of possible geometries for DCMT inserts. Inserts that are round or circular are utilized in processes such as button milling and radius groove turning, respectively. Some varieties may be adjusted so that unused areas of the edge can be utilized once a portion of the edge has been worn away.

The triangle and the trigon are both examples of three-sided insert forms. Inserts in the shape of triangles have a triangular shape, with three sides equal in length and three points comprising angles of sixty degrees each. A trigon insert is a three-cornered insert that looks like a triangle but has an altered triangular shape. It can take the form of bent sides or intermediate angles on the sides, enabling greater included angles to be achieved at the insert’s points.

DCMT Inserts

Diamonds, squares, rectangles, and rhombic are examples of forms with four sides called inserts. To remove material, and insert having four sides, and two sharp angles are known as a diamond insert. Square cutting tips feature four equal sides. Rectangular inserts have four sides, with two being longer than the other two sides. Grooving is a common application for these inserts; the actual cutting edge is located on the shorter edges of the insert. Inserts known as rhombic or parallelograms have four sides and are angled on all four sides to provide clearance for the cutting point.

Inserts can also be made in the shape of a pentagon, which has five sides equal in length, and octagonal inserts, which have eight sides.

Various types of inserts may be distinguished from one another based on the tip angles of the inserts, in addition to the geometry of the inserts themselves. An insert with a hemispheric “ball nose” whose radius is one-half of the cutter diameter is known as a ball nose mill. This mill type is excellent for cutting female semicircles, grooves, or radii. Typically utilized on milling cutters, a radius tip mill is a straight insert with a grinding radius on the tips of the cutting edges. Typically attached to milling cutter holders, chamfer tip mills have to insert sides or ends that have an angled area on the tip. This section allows the mill to create a workpiece with an angled cut or a chamfered edge. An insert known as a dogbone has two cutting edges, a thin mounting core, and, as the name suggests, wider cutting features on both ends. This type of insert is typically used for grooving. The angle of the included tip can range from 35 to 55 degrees, as well as 75, 80, 85, 90, 108, 120, and 135 degrees.

Specifications

In general, insert size is classified according to the inscribed circle (I.C.), also known as the circle’s diameter that fits within the insert geometry. This is used for most indexable inserts, except for rectangular and some parallelogram inserts, which utilize length and width instead. Important DCMT insert requirements are the thickness, the radius (if applicable), and the chamfer angle (if applicable). The terms “unground,” “indexable,” “chip breaker,” and “dished” are frequently used to describe the characteristics of DCMT inserts. Attachments for inserts can either be screwed on or have no hole.

Materials

Carbide, micro-grain carbides, CBN, ceramic, cermet, cobalt, diamond PCD, high-speed steel, and silicon nitride are the most prevalent materials used in the construction of DCMT inserts. Wear resistance and insert life can both be increased with the use of coatings. Coatings for DCMT inserts include titanium nitride, titanium carbonitride, titanium aluminum nitride, aluminum titanium nitride, aluminum oxide, chromium nitride, zirconium nitride, and diamond DLC.