WNMG INSERT VARIETIES

CHIPBREAKER

Finish cutting (FH) is the First choice for carbon steel, alloy steel, and stainless steel finishing. Chip breaker with two sides. Even at shallow depths of cut, chip control is stable

Cut depth: up to 1m

0.08 to 0.2mm feed rate

LM

LM stands for light cutting. Burr control is excellent. Because the sharpness qualities and cutting edge strength are optimized with varying rake angles, the incidence of burrs is dramatically reduced.

Cut depth: 0.7 – 2.0

Feeding frequency: 0.10 – 0.40

LP

LP – Very light cutting. Butterfly protrusions are tailored to specific cutting circumstances. Chips curl upwards, reducing cutting resistance and resulting in better surface finishes. The breaker protrusion is exceptionally resistant to wear even during high-speed milling, allowing for lengthy durations of steady chip breaking. Excels at copy machining: has a sharp edge shape that produces good chip breaking during copy machining and reverses direction face machining.

Depth of cut: 0.3 – 2.0

Feed rate: 0.10 – 0.40

GM

GM – The primary LM and MM chipbreaker’s sub breaker. For light to medium cutting, it has excellent notch resistance.

Cut depth: 1.0 – 3.5

Feed rate: 0.10 – 0.35

MA

MA – For medium carbon and alloy steel cutting. Chip breaker has two sides and a positive land for the strong cutting action.

Cut depth: 0.08 to 4mm

0.2 to 0.5mm

MP

MP feed rate – Medium slicing. It is suitable for various copy-turning situations, removing the need for different insert kinds. The inner side of the butterfly protrusion features a sharp gradient, which improves chip-breaking efficiency on minor cuts.

Cut depth: 0.3 – 4.0

Feed rate: 0.16 – 0.50

MS

MS – Medium cutting rate for difficult-to-machine materials. Ideal for nickel-based alloys, titanium, and stainless steel.

Cut depth: 0.40-1.8

Feed rate: 0.08 – 0.20

MW

MW – Wiper inserts for medium carbon and alloy steel cutting. Chipbreaker has two sides. The wiper can double the feed rate. The large chip pocket reduces jamming.

Cut depth: 0.9 – 4.0

Rough cutting feed rate: 0.20 – 0.60

RM

RM Outstanding fracture resistance. High cutting edge stability is accomplished during interrupted machining by adjusting the land angle and honing geometry.

Cut depth: 2.5 – 6.0

Rough cutting feed rate: 0.25 – 0.55

RP

RP The peninsular protrusion has been optimized for rough cutting. The increasingly slanted cutting face decreases crater wear and prevents clogging. High fracture resistance: the cutting flute has a robust flat-land form and a large chip pocket to prevent clogging and fracturing during chamfering.

Cut depth: 1.5 – 6.0

Feeding frequency: 0.25 – 0.60

Include problems.

What factors should a shop consider when selecting an indexable insert for a cutting application? In many circumstances, this is likely not how the decision is reached.

Instead of defaulting to the familiar, the best way is to examine the cutting process in detail and then pick an insert with the appropriate features to satisfy the needs and requirements of that application. Insert providers might be of great assistance in this respect. Their expertise can guide you to an insert that is ideal for a specific work but will also assist maximize productivity and tool life.

Before deciding on the best insert, businesses should assess if a detachable cutting tip is a better solution for a project than a reliable tool. One of the most appealing aspects of inserts is that they typically have more than one cutting edge. When a cutting edge becomes worn, it can be replaced by rotating or flipping the insert, commonly known as indexing, to a new edge.

However, indexable inserts are not as hard as solid tools and hence are not as precise.

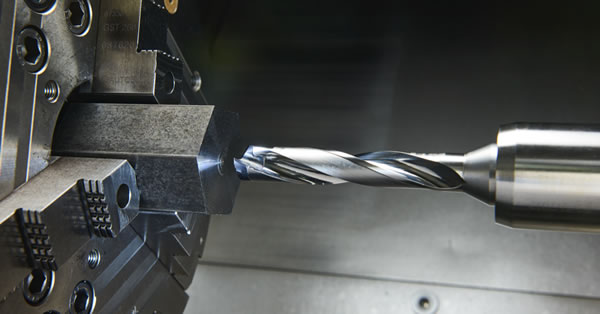

STARTING THE PROCEDURE

When the choice to use an indexable insert is made, retailers are faced with a plethora of possibilities. Decide what you want to achieve with the insert as an excellent place to start selecting. While productivity may be the key concern in certain organizations, others may value flexibility more and prefer an insert that can be used to produce several sorts of comparable components, he noted.

Another factor to consider early in the insert selection process is the application, namely, the material to be machined.

Modern cutting tools are material-specific, so you can’t just pick an insert grade that works well in steel and expect it’ll work well in stainless, superalloys, or aluminum.”

Toolmakers provide several insert grades — from more wear-resistant to harder — and geometries to handle a wide range of materials, as well as material circumstances such as hardness and whether a material is cast or forged.

If you’re (cutting) a clean or pre-machined material, your grade option will be different than if you’re (cutting) a cast or forged component. Furthermore, geometry choices for a cast component will differ from that of a pre-machined component.”

Shops should also consider the machines in which an insert will be